Certified Sprinkler System Testing for Safety & Compliance

Regular inspection and maintenance of commercial fire sprinkler systems are essential to ensure compliance with BS EN 12845, the current British Standard governing the design, installation, and maintenance of fire sprinkler systems in commercial and industrial premises.

It is required to undertake routine checks at specific intervals to guarantee reliability and performance in the event of a fire.

_HEIC.png)

Why Regular Testing is Important

Commercial and industrial properties rely heavily on automatic sprinkler systems as a primary fire suppression method.

Without regular testing and maintenance, small defects can develop into major failures compromising safety, insurance compliance, and legal obligations.

Routine servicing in line with BS EN 12845 ensures that:

-

Your system remains fully operational and compliant.

-

Critical components such as pumps, valves, and alarms function as intended.

-

You maintain insurance validity and meet fire risk assessment requirements.

-

The system is always ready to protect lives, assets, and business continuity.

What is Involved in a Commercial Sprinkler Service

System Isolation & Notifications

Alarm systems, fire brigades, and monitoring stations are informed prior to testing to prevent false alarms.

Flow & Pressure Testing

Measuring flow and pressure at test points to ensure system design parameters are maintained.

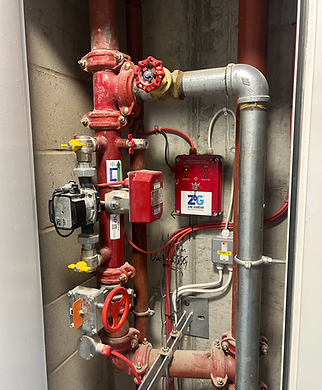

Control Valve & Alarm Valve Inspection

Ensuring valves are correctly positioned, accessible, sealed, and operating freely.

Alarm & Flow Switch Testing

Confirming alarm transmission and flow switch response meet the required standard.

Pump Testing & Flow Verification

Both electric and diesel-driven fire pumps are tested for automatic and manual start, water flow rate, and pressure in accordance with BS EN 12845.

Sprinkler Head & Pipework Inspection

Checking for corrosion, paint, dust, or obstructions on sprinkler heads; visual checks for pipe condition and support integrity.

Water Supply & Tank Inspection

Verifying tank integrity, water levels, and replenishment systems. Includes visual and functional inspection of associated equipment such as jockey pumps and pressure maintenance devices.

Comprehensive Reporting

A detailed maintenance report outlining system performance, faults found, corrective actions recommended, and confirmation of compliance with BS EN 12845.

Service Frequency

BS EN 12845 specifies a structured maintenance schedule for commercial sprinkler systems:

Quarterly

Test dry alarm valve operation, inspect water motor alarms, check water supply arrangements, and inspect electrical control panels.

Half-Yearly

Conduct flow tests on pumps, check diesel and electric pump performance, verify tank water levels, and assess general condition of all mechanical components.

Annually

Full system inspection and testing, including functional tests of alarms, pumps, flow switches, pressure maintenance devices, and water supply arrangements. A comprehensive report is issued detailing compliance with BS EN 12845.

Every 3 Years

A full overhaul and internal inspection of pipework and storage tanks to identify corrosion or obstructions.

Every 10 Years (as recommended)

A full overhaul and internal inspection of pipework and storage tanks to identify corrosion or obstructions.

Why Choose Us

We specialise in the inspection, testing, and maintenance of Ordinary Hazard (OH1 and OH2) commercial fire sprinkler systems, fully compliant with BS EN 12845.

Our services ensure that your system operates efficiently, meets all regulatory standards, and remains ready to always protect your property.

We provide tailored support for a wide range of commercial and public environments, including:

OH1: Offices, hotels, schools, restaurants, and healthcare facilities…

OH2: Retail spaces, car parks, museums…

Our qualified engineers are fully trained and accredited to maintain systems in line with BS EN 12845, delivering reliable performance, thorough documentation, and complete peace of mind for every client.

Contact our team of experts

Contact us to discuss your servicing requirements. Our services are available across the whole of Mainland UK.